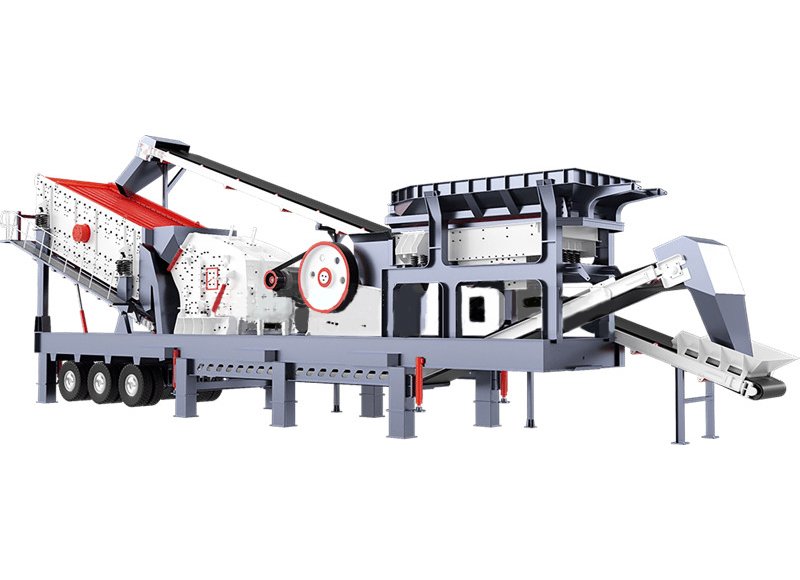

Mobile Screening Plant For Sale

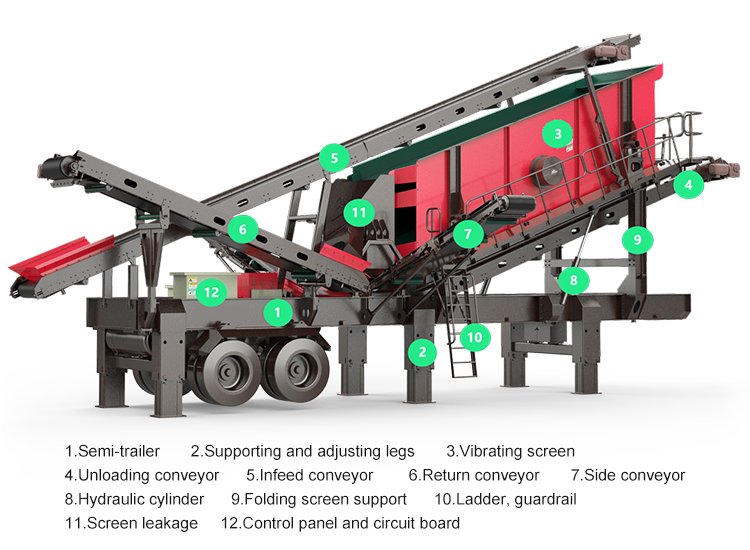

Mobile electric vibrating screen with vibrating screen, mounted on a semi-trailer with conveyor and control unit, transported by a truck tractor, can be flexibly moved from one location to another.

- 【Feeding Size】: ≤ 80mm

- 【Number of screens】: ≤3

- 【Capacity】: ≤750T/H

- 【Crushing materials】: Cobblestone, gravel, granite, basalt, minerals, quartz, pyroxene, limestone, ores, slag, coal, and more.

- 【Applications】: Mining, metallurgy, civil engineering, road construction, railroad, berth construction, coal industry, gold mining, chemical industry, recycling, etc.

Relevant Parameters of Mobile Screening Plant for Sale

The Movable Screener is a range of sorting equipment configured to customer requirements, compactly mounted on a wheeled vehicle semi-trailer. The standard configuration can be modified to meet customer requirements and comes complete with various components such as a receiving hopper with primary screen grid, control room, diesel engine generator etc. The secondary screen is fitted with a pallet and the primary screen with a hopper and an inclined grate.

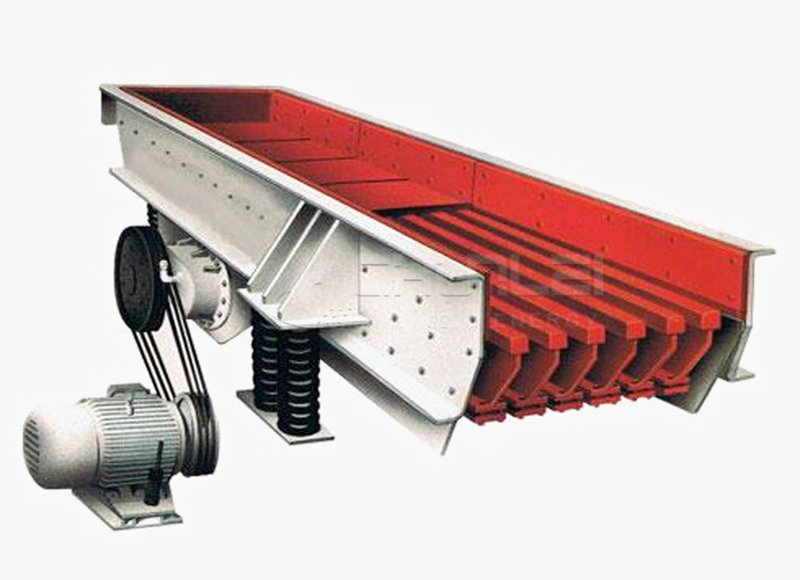

This series of mobile screening stations uses eccentric inclined vibrating screens designed for mechanical sorting of bulk raw materials. The working principle is that the material moves along the honeycomb grid of the inclined deck under vibration, which is generated by the eccentric block connected to the motor through a soft coupler.

| Series | Standard Model | Vehicle-mounted Equipment | Vehicle-mounted Equipment | Processing Capacity (t/h) | Transportation Dimensions (mm) |

| Four Combination Mobile Station | MTN100Y-2 | GZD850X3000/2YK1545 | HD72/GYS300 | 50-100 | 15000x2650x4500 |

| MTN100Y-3 | GZDT0835/3HX1548 | HDX86/SC100F1 | 50-100 | 17500x2500x4000 | |

| MTN150Y-3 | GZDT0835/3HX1548 | HDX86/SC160F1 | 70-150 | 17500x2500x4000 | |

| MTN150R-3 | GZDT0835/3HX1548 | HDX86/CI1110 | 60-150 | 17500x2500x4000 | |

| Coarse Crushing Mobile Station | MTN96 | GZDT9538 | CJ96 | 70-200 | 13000x2950x4250 |

| MTN98 | GZDT9538 | HDX98 | 80-200 | 13000x2950x4250 | |

| MTN106 | GZDT1145A | CJ106 | 90-300 | 14000x3000x4400 | |

| MTN110 | GZDT1145A | HDX110 | 120-300 | 14000x3000x4400 | |

| MTN1213C | GZDT9538 | CI1213 | 80-200 | 13000x2950x4250 | |

| MTN1316C | GZDT1145A | CI1316 | 100-300 | 14000x3000x4400 | |

| Medium and Fine Crushing Mobile Station | MTN300 | – | HPM300C1 | 100-200 | 15500x2900x4200 |

| MTN400 | – | HPM400C3 | 150-300 | 16500x3100x4300 | |

| MTN250 | – | SC250F1 | 90-200 | 16500x3100x4300 | |

| MTN1213 | – | CI1213 | 80-200 | 16000x2900x4300 | |

| MTN1316 | – | CI1316 | 100-300 | 16500x3100x4500 | |

| MTN0926 | – | HVI0926 | 85-200 | 16500x3100x4300 | |

| MTN1040 | – | HVI1040 | 120-300 | 16500x3100x4400 | |

| Screening Mobile Station | MTN1865-3 | – | 3HX1865 | 65-200 | 14500x2900x4000 |

| MTN2165-3 | – | 3HX2165 | 85-300 | 15000x2900x4400 | |

| Medium and Fine Crushing and Screening Mobile Station | MTN300S-3SII | 3HX1865 | HPM300C1 | 100-200 | 15000x3000x4000 |

| MTN300S-3 | 3HX2165 | HPM300C1 | 100-200 | 15000x3000x4000 | |

| MTN400S-3 | 3HX2165 | HPM400C3 | 150-300 | 15000x3000x4000 | |

| MTNG400S-3SII | 3HX1865 | GYS400C1 | 100-200 | 15000x3000x4000 | |

| MTNG400S-3 | 3HX2165 | GYS400C1 | 100-200 | 15000x3000x4000 | |

| MTN250S-3 | 3HX2165 | SC250F1 | 90-200 | 15000x3000x4200 | |

| MTN1213S-3 | 3HX1865 | CI1213 | 80-200 | 15000x3000x4200 | |

| MTN1316S-3 | 3HX2165 | CI1316 | 100-300 | 15000x3000x4200 | |

| MTN0926S-2 | 2HX1865 | HVI0926 | 85-200 | 18000x3000x4200 | |

| MTN1040S-2 | 2HX2165 | HVI1040 | 120-300 | 18000x3000x4200 | |

| Three Combination Mobile Station | MTN1213-III | GZDT9538/3HX1865 | CI1213 | 80-200 | 18200x2800x4350 |

| MTN1316-III | GZDT1145A/3HX2165 | CI1316 | 100-300 | 18200x3000x4200 | |

| MTN1410-III | GZDT9538/3HX1865 | PCZ1410 | 80-200 | 18200x2800x4200 | |

| MTN1612-III | GZDT1145A/3HX2165 | PCZ1612 | 100-300 | 18200x3000x4200 |

Note: The output will vary depending on different materials, feed particle size and other factors.

The Mobile Screening Plant can be customized according to production capacity, geography, climate and other factors, and the color can be customized according to customer requirements.

Features of Mobile Screening Plant Machine

Modularized design: adopts modularized universal design, each part is independent. The host can be replaced to realize the conversion between different models and shorten the supply cycle.

Unique integration: The fully automatic wheeled mobile crushing plant is composed of feeding, crushing, screening, conveying and other systems, realizing online integrated production.

Foundation-free installation: the vehicle-mounted mobile does not need to build a large concrete foundation, which reduces the labor force and lowers the requirements for the construction site.

Fully intelligent control: the equipment adopts PLC centralized control, touch screen display, detecting machine operation at any time. Equipped with independent electric control system, easy to operate.

Convenient transfer: the length of the equipment is between 12-16 meters, easy to move. The conveyor belt can be retracted and folded to reduce the high transportation cost of materials.

Working Principle of Mobile Screening Plant

The motor through the triangle belt makes the exciter eccentric block produce high-speed rotation. The running eccentric block generates a large centrifugal force, which excites the screen box to produce a certain amplitude of circular motion, and the materials on the screen are subjected to the impulse transmitted by the screen box on the inclined screen surface to produce a continuous throwing motion, and the materials and the screen surface meet in the process of making the particles smaller than the screen holes through the sieve, thus realizing the grading.

Mobile Screening Plant Application in Crushing Plants

Mobile Screening Plant is widely used in the following fields:

Mining mines: Mobile Screening Plant crushes the mined large ores to improve the beneficiation efficiency and metal recovery rate.

Building materials: crushing limestone, granite, etc. for manufacturing building materials such as sand, gravel and aggregate.

Chemical industry: Mobile Screening Plant is used to crush various kinds of coal, coke, gypsum and other chemical raw materials.

Water conservancy project: to provide sand and gravel materials required for water conservancy project construction.

Highway and railroad construction: Mobile Screening Plant crushes various road base materials such as stone and gravel, and the crushed materials are used for laying road base and pavement.

Metallurgical industry: crushing scrap steel, scrap iron, slag and other metal ores to provide raw materials for smelting.

What Are The Main Components of Stone Crushing Plants?

A stone crushing plant consists of several key components, each of which is critical to the efficient crushing, screening and sorting of raw materials. Here are a few key components for you:

Feeder

Vibrating feeder, which can control the feeding speed of raw materials into the stone crusher, allowing smooth and continuous crushing operation.

Jaw Crusher

Jaw crusher, which can be used for primary crushing of large rocks, crushing large stones into small sizes for secondary crushing. This is the first stage of the crushing process.

Cone Crusher

Cone crusher, used in secondary crusher, further reduces the size of the material processed by the primary crusher to obtain finer material.

Impact Crusher

Impact crushers are vital for producing finely crushed material utilizing high velocity impact and are ideally suited for producing uniformly sized construction aggregates.

Screening Machine

Screens are mainly used after crushing to separate different sizes of material. Vibrating screens are commonly used to sort and classify crushed stone.

Conveyor Belt

Conveyor belts bridge the entire production line, mainly transporting material between different stages, they connect the entire system and ensure a smooth flow of material.

How Does A Stone Crusher Plant Work?

After the main equipment of stone crushing production line is understood, the following is the working principle of stone crushing production line. The efficient operation of stone crushing production line relies on the synergy of various components, which play an important role in the whole process. How does each component play a role in the whole production line?

What Should You Consider When Choosing Mobile Screening Plant?

If you are planning to buy a Mobile Screening Plant, then you need to consider many factors in advance, such as capacity, feed size, discharge aggregate size, application, price, service, return and so on. Here I have listed a few important parts for your reference:

Feeding size

The first thing you should consider is the feed size. Customers should probably know the size of the material aggregate before crushing. Because customized Mobile Screening Plant models are mainly divided according to the feed size.

Capacity

Capacity should also be one of the factors to consider. If you plan to crush a large amount of aggregate in a short period of time, it is better to choose a large capacity crusher. If there is enough time, a smaller size crusher may be more cost effective.

Price

Mobile Screening Plant cost is the most important aspect for customers to consider. It is very important for customers to choose a Mobile Screening Plant with the best price and within their budget. Chunlei offers different models of crushers with different prices. Please contact us and get the latest Mobile Screening Plant price.

Service

For mining machinery industry, choosing a reliable and serviceable Mobile Screening Plant manufacturer is very important for customers. Crushing production line is a complete set of solutions customized for customers. Therefore, it needs constant communication, follow-up and feedback. The best service can help customers save a lot of maintenance after-sales service costs.

For the mining industry, especially for large-scale mining machinery, it is especially important for customers to choose a reliable and well-served Mobile Screening Plant manufacturer. The crushing line is a complete solution customized for the customer. Therefore, both parties need constant communication, follow-up and feedback. Meticulous service can help customers save a lot of maintenance and after-sale costs.

What Can ChunLei Do for You About Mobile Screening Plant Service?

- Pre-sales service: 1.Assist customers to prepare the first construction plan; 2. Provide route guidance, reception at any time, and visit our factory at any time.

- On-sale service: 1. Provide example guidance at any time by phone or email; 2. Install, debug and inspect the equipment, and provide technical support through video.

- After-sales service: 1. Provide spare parts at the best price for a long time; 2. We provide 1 year warranty and technical support to ensure the smooth operation of the machine.

You may also want to know about ChunLei-FAQ

1. Are you a factory or a trading company?

We are factory, and in 2008 officially registered ChunLei Machinery.

2.How is the quality of your products?

Our products are manufactured strictly according to national and international standard, and we take a test on every equipment before delivery.

3.How about price?

We are factory and can give you lower price than the market, and we have a policy “In order to save time and absolutely honest business attitude, we provide the lowest possible quotation for any customer, and can give discounts as needed to the quantity” .

4. How long is the warranty?

Does your company supply the spare parts? One year. Spare parts for you at lowest cost.

5. How long is your delivery time?

7-10 days for the stock, 15-30 days for the mass production.

6. What is your payment method?

We usually accept T/T, L/C、Western Union payments;

7. If I need a complete mining rig, can you help us build it?

Yes, we can help you set up a complete production line and give you related professional advice. We had already build many mining projects in China & Overseas.

Customize Your crushing Solutions

Contact us now via email: info@miningmachinerys.com, or WhatsApp me, or fill in the form below.

1. Feeding Size.

2. What configuration do you need? (Crusher Type , VibratorScreening,Magnetic Separator, Sand Washing Machine, etc.)

3. ls there a Mining License?

4. Start time of project?

5. Other requirement.

Contact information: