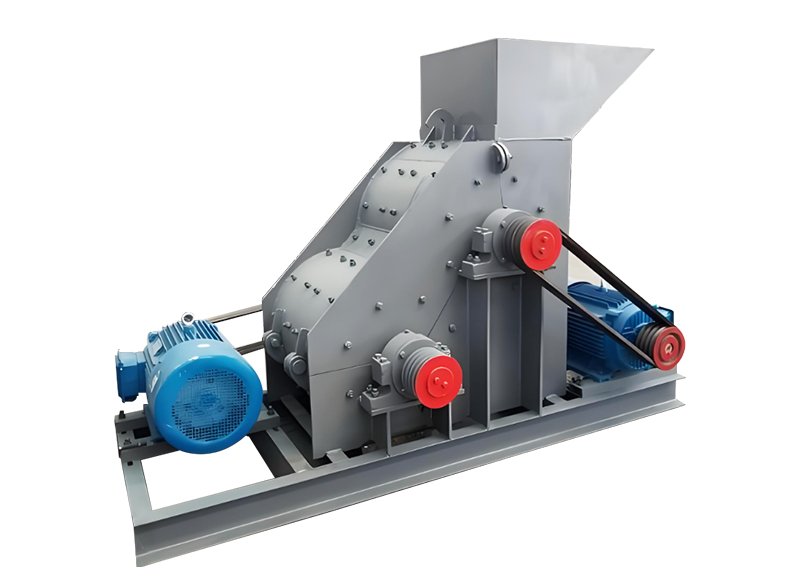

Double Stage Crusher For Sale

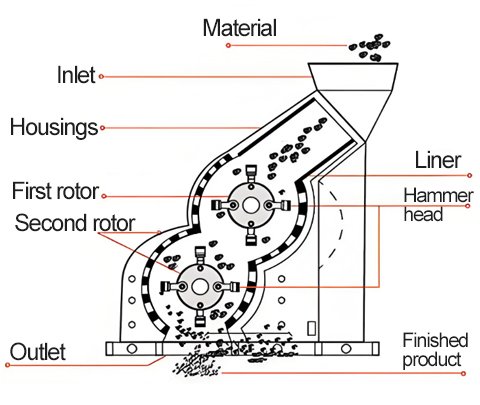

Double-stage crusher is also called no screen low double-stage crusher, in the design did not use the screen grate bottom, there is no strict requirements for the moisture content of the material, there is no paste plugging screen phenomenon, can completely overcome the raw material due to the moisture content of the large bonding grate bottom, it is not easy to discharging the defects.

- 【Feeding Size】: ≤ 220mm

- 【Output Size】: ≤3mm

- 【Capacity】: 10 –300T/H

- 【Crushing materials】: Calcite, limestone, brick factory cinder, slag, slag, shale, coal gangue, construction waste, construction waste and other materials crushing.

- 【Applications】: Solve the gangue, cinder for brick factory additives, internal fuel; gangue, shale production of standard bricks, hollow bricks with high wet material crushing problems.

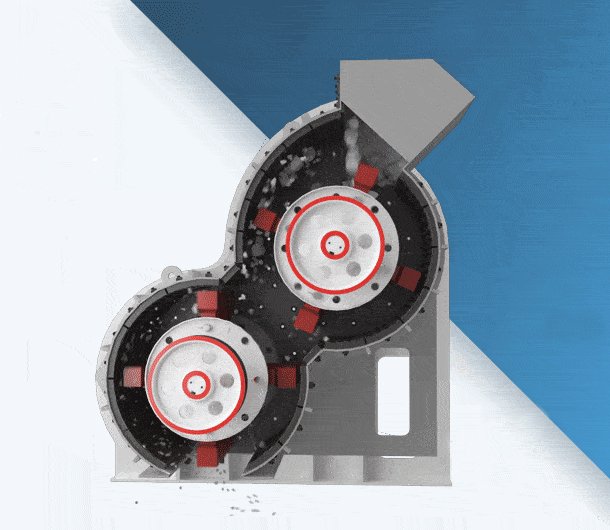

In addition, in terms of production capacity, the double-stage crusher is equivalent to the two hammer breakers combined into one, the two groups of hammer breakers rotor combination into a whole and serial use, is currently a new type of It is a new type of raw material crusher.

Type of Double Stage Crusher for Sale – Single Equipment

Double-stage crusher mainly consists of body, eccentric shaft, big pulley and flywheel, movable jaw body, electric motor, discharge opening adjustment device, castor adjusting mechanism and so on.

Special design parts of double stage crusher:

Double rotor: The core component of the double-stage crusher is composed of two rotors connected in series. The material first enters the upper rotor for initial crushing, and then enters the lower rotor for secondary crushing to ensure uniformity and fineness of the discharged material.

Hammer head: Installed on the rotor, it is used for striking and crushing the materials. The hammer head is made of wear-resistant material, which prolongs the service life.

Liner: It is used to protect the inner wall of the crusher and prevent the material from wearing out the body of the crusher. The liner is also made of wear-resistant material.

Model | Feeding Size (mm) | Discharge size(mm) | Capacity (t/h) | Motor Power (kw) | Overall Dimension (mm) | Weight(t) |

2PC 600×400 | ≤110 | ≤3(可调) | 10-15 | 18.5+18.5 | 2350*926*1630 | 1.3 |

2PC 600×600 | ≤110 | ≤3(可调) | 15-20 | 22+22 | 2875*1300*1650 | 1.6 |

2PC 600×800 | ≤110 | ≤3(可调) | 20-30 | 30+22 | 2800*1360*1600 | 2.4 |

2PC 800×600 | ≤110 | ≤3(可调) | 30-40 | 45+37 | 3625*1314*2065 | 3.5 |

2PC 800×800 | ≤120 | ≤3(可调) | 40-50 | 55+45 | 3485*1400*254 | 3.9 |

2PC 1000×800 | ≤120 | ≤3(可调) | 50-60 | 55+75 | 3950*1750*2280 | 6 |

2PC 1000×1000 | ≤120 | ≤3(可调) | 60-90 | 90+75 | 4086*2030*2337 | 7.5 |

2PC 1000×1200 | ≤180 | ≤3(可调) | 70-90 | 90+110 | 3800*2000*2400 | 8.6 |

2PC 1200×1400 | ≤200 | ≤3(可调) | 120-130 | 132+160 | 5900*2658*3210 | 9.7 |

2PC 1400×1600 | ≤200 | ≤3(可调) | 130-180 | 160+200 | 6000*3100*3900 | 13.8 |

2PC 1600×2000 | ≤220 | ≤3(可调) | 200-300 | 400+400 | 6580*3400*4200 | 19.8 |

Note: The output will vary depending on different materials, feed particle size and other factors.

The Double Stage Crusher can be customized according to production capacity, geography, climate and other factors, and the color can be customized according to customer requirements.

Features of Double Stage Crusher Machine

Special shift gap technology, hammer head wear and tear without repair, move the position of repeated use, a hammer head can top three sets of hammer head use.

Uniform particle size, large crushing ratio, high output, low energy consumption, can crush more than 20 tons of material per hour, the cost of crushing each ton of cinder is not more than 1.8 yuan.

Double-stage crusher is suitable for fine crushing of brittle materials, no clogging, less dust, low noise.

No sieve low double-stage crusher shortens the time that the material stays in the crushing cavity, and improves the service life of wearing parts.

Quick maintenance, the crusher on the upper side of the side door can be open, thus making the crusher maintenance and easy to damage.

The high alloy wear-resistant hammer head is adopted, and the hammer head and hammer shank are used in combination, only the hammer head is changed, not the hammer shank.

Bi-directional rotation, through the continuous iso-shift bi-directional operation, can facilitate the uniform wear between the hammer head and the crushing plate, reducing the frequency of downtime to replace wearing parts.

Working Principle of Double Stage Crusher

When the double-stage crusher works, driven by the double motors, the two sets of rotors in series with each other rotate at high speed at the same time, the materials in the inner cavity of the machine by the upper rotor crushed immediately by the hammer of the lower rotor rotating at high speed to be finely crushed again, and the materials in the inner cavity collide with each other at high speed to crush each other, to achieve the effect of the hammer powder, material powder, to form the cinder particles with the particle size of the discharge of less than 3 millimeters. This granularity can fully meet the requirements of brick manufacturers as internal combustion brick making.

Double Stage Crusher Application in Crushing Plants

Double Stage Crusher is widely used in the following fields:

Mining industry: double stage crusher can be used to process various hardness ores such as granite, basalt and so on.

Metallurgical industry: The double stage crusher can be used for crushing and fine crushing of large quantities of ores and wastes.

Building materials industry: the double-stage crusher can be used to crush large stones into sand and gravel aggregate particles that meet the requirements.

Chemical industry: The double-stage crusher can be used to handle the crushing and grinding of materials required in the preparation of chemical raw materials to meet the needs of chemical production.

Coal industry: The double-stage crusher can be used for crushing and screening of coal briquettes.

Its wet and dry features enable it to perform well in handling materials such as coal slurry with high water content.

Refractory industry: The double-stage crusher can crush and finely crush the raw materials required in the preparation of refractory materials, ensuring the quality and performance of refractory materials.

What Should You Consider When Choosing Double Stage Crusher?

If you are planning to buy a Double Stage Crusher, then you need to consider many factors in advance, such as capacity, feed size, discharge aggregate size, application, price, service, return and so on. Here I have listed a few important parts for your reference:

Feeding size

The first thing you should consider is the feed size. Customers should probably know the size of the material aggregate before crushing. Because customized Double Stage Crusher models are mainly divided according to the feed size.

Capacity

Capacity should also be one of the factors to consider. If you plan to crush a large amount of aggregate in a short period of time, it is better to choose a large capacity crusher. If there is enough time, a smaller size crusher may be more cost effective.

Price

Double Stage Crusher cost is the most important aspect for customers to consider. It is very important for customers to choose a Double Stage Crusher with the best price and within their budget. Chunlei offers different models of crushers with different prices. Please contact us and get the latest Double Stage Crusher price.

Service

For mining machinery industry, choosing a reliable and serviceable Double Stage Crusher manufacturer is very important for customers. Crushing production line is a complete set of solutions customized for customers. Therefore, it needs constant communication, follow-up and feedback. The best service can help customers save a lot of maintenance after-sales service costs.

For the mining industry, especially for large-scale mining machinery, it is especially important for customers to choose a reliable and well-served Double Stage Crusher manufacturer. The crushing line is a complete solution customized for the customer. Therefore, both parties need constant communication, follow-up and feedback. Meticulous service can help customers save a lot of maintenance and after-sale costs.

What Can ChunLei Do for You About Double Stage Crusher Service?

- Pre-sales service: 1.Assist customers to prepare the first construction plan; 2. Provide route guidance, reception at any time, and visit our factory at any time.

- On-sale service: 1. Provide example guidance at any time by phone or email; 2. Install, debug and inspect the equipment, and provide technical support through video.

- After-sales service: 1. Provide spare parts at the best price for a long time; 2. We provide 1 year warranty and technical support to ensure the smooth operation of the machine.

You may also want to know about ChunLei-FAQ

1. Are you a factory or a trading company?

We are factory, and in 2008 officially registered ChunLei Machinery.

2.How is the quality of your products?

Our products are manufactured strictly according to national and international standard, and we take a test on every equipment before delivery.

3.How about price?

We are factory and can give you lower price than the market, and we have a policy “In order to save time and absolutely honest business attitude, we provide the lowest possible quotation for any customer, and can give discounts as needed to the quantity” .

4. How long is the warranty?

Does your company supply the spare parts? One year. Spare parts for you at lowest cost.

5. How long is your delivery time?

7-10 days for the stock, 15-30 days for the mass production.

6. What is your payment method?

We usually accept T/T, L/C、Western Union payments;

7. If I need a complete mining rig, can you help us build it?

Yes, we can help you set up a complete production line and give you related professional advice. We had already build many mining projects in China & Overseas.

Customize Your crushing Solutions

Contact us now via email: info@miningmachinerys.com, or WhatsApp me, or fill in the form below.

1. Feeding Size.

2. What configuration do you need? (Crusher Type , VibratorScreening,Magnetic Separator, Sand Washing Machine, etc.)

3. ls there a Mining License?

4. Start time of project?

5. Other requirement.

Contact information: