KJ Series Modular Crushing Plant For Sale

Features of KJ Series Modular Crushing Plant Machine

Modularized design, fast production

Modular and integrated design, each functional module can be freely combined according to the project requirements, facilitating rapid installation and production, more flexible equipment layout, the site is more concise and reasonable.

Highly automated configuration

Equipped with advanced automation control system and high-quality maintenance platform, fully considering the maintenance space and convenience of operators, it makes the equipment maintenance more convenient and improves the overall efficiency of the production line.

High-quality host

The mainframe equipment are all high-performance mainframes produced by new industry technology, with high efficiency, high output, fewer failures, easy operation and maintenance, and stable and reliable operation.

Foundation-free installation

The frame structure layout makes each crushing and screening equipment save the cost and time of making concrete foundation on site, which greatly reduces the preparation time and investment in the pre-production stage.

Convenient transportation

The whole machine is unfolded when working, and can be conveniently contracted and folded when transporting, minimizing disassembly and meeting the smooth transportation on domestic highway.

Relevant Parameters of KJ Series Modular Crushing Plant for Sale – Single Equipment

| Series | Standard Model | Vehicle-mounted equipment | Vehicle-mounted equipment | Capacity(t/h) | Transportation Size(mm) |

| Jaw Crushing Plant | KJ98 | GZDT9538 | HDX98 | 90-350 | 12750×3020×3850 |

| KJ110 | GZDT1145B | HDX110 | 120-450 | 13050×3050×4000 | |

| Impact Crushing Plant | KJ1213 | GZDT9538 | C11213 | 80-320 | 12970×3020×3920 |

| KJ1316 | GZDT1145B | C11316 | 100-400 | 13290×3050×4080 | |

| Cone Crushing Plant | KJ300 | – | HPM300C1 | 60-280 | 15650×3270×3780 |

| KJ250 | – | SC250F1 | 90-350 | 15600×32700×3800 | |

| Sand Crushing Plant | KJ0926 | – | HVI0926 | 85-240 | 15400×2770×3780 |

| KJ1040 | – | HVI1040 | 120-284 | 15400×2920×3970 | |

| Screening Station | KJ1865S-3 | – | 3HX1865 | 65-350 | 15200×2900×3000 |

| KJ2165S-4 | – | 4HX2165 | 85-500 | 15200×2900×3200 |

Note: According to different materials, feed size and other factors, the results will be different.

The KJ Series Modular Crushing Plant can be customized according to production capacity, geography, climate and other factors, and the color can be customized according to customer requirements.

How Does A Stone Crusher Plant Work?

After the main equipment of stone crushing production line is understood, the following is the working principle of stone crushing production line. The efficient operation of stone crushing production line relies on the synergy of various components, which play an important role in the whole process. How does each component play a role in the whole production line?

What Are The Main Components of Stone Crushing Plants?

A stone crushing plant consists of several key components, each of which is critical to the efficient crushing, screening and sorting of raw materials. Here are a few key components for you:

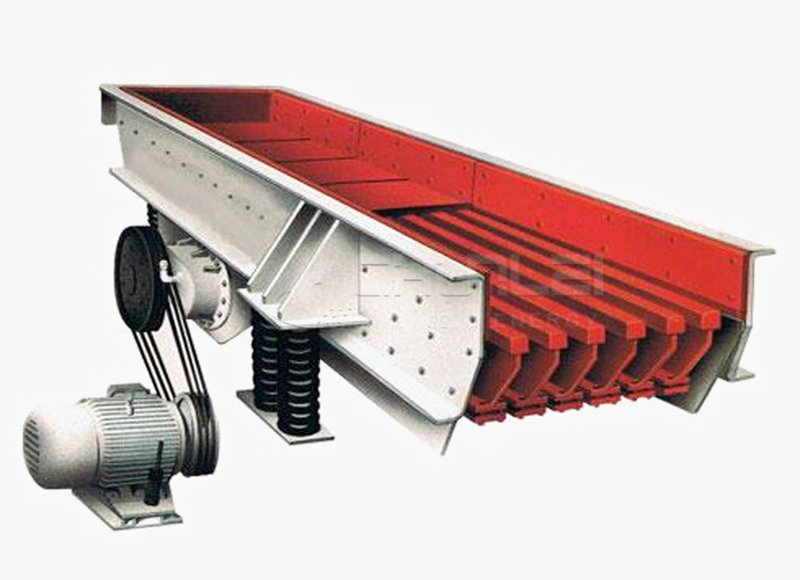

Feeder

Vibrating feeder, which can control the feeding speed of raw materials into the stone crusher, allowing smooth and continuous crushing operation.

Jaw Crusher

Jaw crusher, which can be used for primary crushing of large rocks, crushing large stones into small sizes for secondary crushing. This is the first stage of the crushing process.

Cone Crusher

Cone crusher, used in secondary crusher, further reduces the size of the material processed by the primary crusher to obtain finer material.

Impact Crusher

Impact crushers are vital for producing finely crushed material utilizing high velocity impact and are ideally suited for producing uniformly sized construction aggregates.

Screening Machine

Screens are mainly used after crushing to separate different sizes of material. Vibrating screens are commonly used to sort and classify crushed stone.

Conveyor Belt

Conveyor belts bridge the entire production line, mainly transporting material between different stages, they connect the entire system and ensure a smooth flow of material.

What Should You Consider When Choosing KJ Series Modular Crushing Plant ?

If you are planning to buy a KJ Series Modular Crushing Plant , then you need to consider many factors in advance, such as capacity, feed size, discharge aggregate size, application, price, service, return and so on. Here I have listed a few important parts for your reference:

Feeding size

The first thing you should consider is the feed size. Customers should probably know the size of the material aggregate before crushing. Because customized KJ Series Modular Crushing Plant models are mainly divided according to the feed size.

Capacity

Capacity should also be one of the factors to consider. If you plan to crush a large amount of aggregate in a short period of time, it is better to choose a large capacity crusher. If there is enough time, a smaller size crusher may be more cost effective.

Price

KJ Series Modular Crushing Plant cost is the most important aspect for customers to consider. It is very important for customers to choose a KJ Series Modular Crushing Plant with the best price and within their budget. Chunlei offers different models of crushers with different prices. Please contact us and get the latest KJ Series Modular Crushing Plant price.

Service

For mining machinery industry, choosing a reliable and serviceable KJ Series Modular Crushing Plant manufacturer is very important for customers. Crushing production line is a complete set of solutions customized for customers. Therefore, it needs constant communication, follow-up and feedback. The best service can help customers save a lot of maintenance after-sales service costs.

For the mining industry, especially for large-scale mining machinery, it is especially important for customers to choose a reliable and well-served KJ Series Modular Crushing Plant manufacturer. The crushing line is a complete solution customized for the customer. Therefore, both parties need constant communication, follow-up and feedback. Meticulous service can help customers save a lot of maintenance and after-sale costs.

What Can ChunLei Do for You About KJ Series Modular Crushing Plant Service?

- Pre-sales service: 1.Assist customers to prepare the first construction plan; 2. Provide route guidance, reception at any time, and visit our factory at any time.

- On-sale service: 1. Provide example guidance at any time by phone or email; 2. Install, debug and inspect the equipment, and provide technical support through video.

- After-sales service: 1. Provide spare parts at the best price for a long time; 2. We provide 1 year warranty and technical support to ensure the smooth operation of the machine.

You may also want to know about ChunLei-FAQ

1. Are you a factory or a trading company?

We are factory, and in 2008 officially registered ChunLei Machinery.

2.How is the quality of your products?

Our products are manufactured strictly according to national and international standard, and we take a test on every equipment before delivery.

3.How about price?

We are factory and can give you lower price than the market, and we have a policy “In order to save time and absolutely honest business attitude, we provide the lowest possible quotation for any customer, and can give discounts as needed to the quantity” .

4. How long is the warranty?

Does your company supply the spare parts? One year. Spare parts for you at lowest cost.

5. How long is your delivery time?

7-10 days for the stock, 15-30 days for the mass production.

6. What is your payment method?

We usually accept T/T, L/C、Western Union payments;

7. If I need a complete mining rig, can you help us build it?

Yes, we can help you set up a complete production line and give you related professional advice. We had already build many mining projects in China & Overseas.

Customize Your crushing Solutions

Contact us now via email: info@miningmachinerys.com, or WhatsApp me, or fill in the form below.

1. Feeding Size.

2. What configuration do you need? (Crusher Type , VibratorScreening,Magnetic Separator, Sand Washing Machine, etc.)

3. ls there a Mining License?

4. Start time of project?

5. Other requirement.

Contact information: