VSI Impact Centrifugal Crusher For Sale

VSI Impact Centrifugal Crusher are specially designed to supply high quality sand and aggregates to highways, high-speed railways, construction, hydroelectric dam construction and concrete mixing plants.

- 【Feeding Size】: 35-50mm

- 【Motor Power】: 110-500kw

- 【Capacity】: 40-650T/H

- 【Crushing materials】: River pebbles, limestone, granite, basalt, gray alumina, andesite, pyroxene, ore tailings, stone chips, iron ore, calcite, steel slag, construction waste and other environmentally friendly recycled materials.

VSI series sand making machine is an impact sand making and shaping machine developed by our company based on the introduction of advanced technology from Germany, combined with the actual situation of sand making production in recent years. In the application of large and super-large mechanism sand and fine aggregate production line, it shows incomparably strong performance.

VSI impact sand making machine is especially suitable for providing sand and gravel aggregate for high-rise buildings, highway (railroad) construction, municipal engineering, large-scale water conservancy facilities, concrete mixing plant and many other fields.

Type of VSI Impact Centrifugal Crusher for Sale – Single Equipment

There are two main feeding methods of VSI sand making machine: complete center feeding and center feeding accompanied by ring cascade feeding.

Complete center feeding: mainly used in “stone to iron” crushing mode, the material is introduced into the inner cavity of the high-speed rotating impeller through the center feeding pipe. This method is suitable for the scenarios that need shaping or have higher requirements on material size.

Center feeding with ring-shaped waterfall feeding: mainly used for “stone to stone” crushing method, part of the material is introduced through the center feeding tube.

Part of the material is introduced into the inner cavity of the impeller through the center feeding pipe, while the other part of the material falls into the inner cavity of the equipment from the overflow ports around the feeding hopper. This method is suitable for sand making scenario with large capacity.

| Model | VSI 7611 | VSI 8518 | VSI 9526 | VSI 1140 | VSI 1145 | VSI 1150 | |

| Processing Capacity (t/h) | Waterfall and Center Feed | 80-180 | 140-260 | 200-380 | 300-520 | 350-610 | 360-650 |

| Full Center Feeding | 40-90 | 70-130 | 100-190 | 160-260 | 180-355 | 190-365 | |

| Working Principlemaximum Feeding Size (mm | Soft Material | 35 | 40 | 45 | 50 | 50 | 50 |

| Hard Material | 30 | 35 | 40 | 40 | 45 | 45 | |

| Speed (r/min) | 1700-1890 | 1520-1690 | 1360-1510 | 1150-1300 | 1150-1300 | 1150-1300 | |

| Motor Power (kw) | 4P 110 | 4P 180 | 4P 264 | 4P 400 | 4P 440 | 4P 500 | |

| Overall Dimensions (Length × Width × Height) (mm) | 4100×2250×2300 | 4160×2360×2500 | 4540×2500×2830 | 5500×2750×3100 | 5500×2750×3100 | 5500×2750×3100 | |

Note: The output will vary depending on different materials, feed particle size and other factors.

The VSI Impact Centrifugal Crusher can be customized according to production capacity, geography, climate and other factors, and the color can be customized according to customer requirements.

Features of VSI Impact Centrifugal Crusher Machine

High output and efficiency: deep cavity impeller design, improve crushing efficiency, increase throughput, material throughput increased by about 30%.

Long service life: core wear-resistant materials, highly wear-resistant and impact-resistant materials. Service life increased by more than 40%, reduce routine maintenance, cost savings, improve efficiency.

Sand grain shape is excellent: the crushing principle optimization design, impact crushing, grain shape is excellent after processing the river pebble sand grains beautiful appearance, gradation with reasonable, fineness modulus adjustable.

Environmental protection in place: the use of deep cavity turbine design, good exhaust system, efficient dust removal equipment to reduce dust pollution; in addition, the smooth operation of the equipment reduces the vibration of the machine body and reduces the noise of the equipment startup and operation.

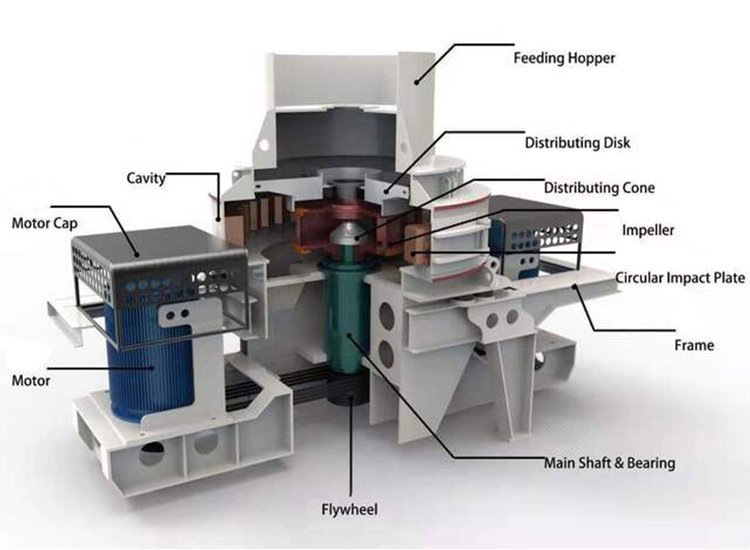

Working Principle of VSI Impact Centrifugal Crusher

VSI sand making machine adopts the advanced selective crushing and solving crushing principle, which can realize the conversion of two working principles: “stone hitting stone” and “stone hitting iron”.

The material is accelerated to tens of times gravity when it enters into the high-speed rotating wheel through the center feeding hole, and then the material is shot out from the wheel at a high speed, which firstly impacts with a part of the material falling freely after rebound (stone hitting stone), and the other part impacts to the material lining (stone hitting iron), and then it is rebounded upward and impacts to the top of the vortex chamber, which then changes the direction of its movement, deflects it to downward movement and then impacts with material launching out from the impeller channel. Then it is rebounded upward to the top of the vortex chamber, which changes its movement direction and deflects downward, and collides with the materials launched from the impeller channel to form a continuous material curtain.

In this way, a piece of material in the vortex crushing chamber by two or more times impact, friction and grinding crushing effect. The crushed material is discharged from the lower discharge port.

VSI Impact Centrifugal Crusher Application in Crushing Plants

VSI Impact Centrifugal Crusher is widely used in the following fields:

Construction industry: In concrete production, the high quality sand produced by VSI sand making machine can reduce the segregation and urination of concrete. It provides high-quality sand and gravel aggregate for highways, high-speed railroads, high-rise buildings, municipal projects, and hydropower dam construction.

Road project: The sand produced by VSI sand making machine can form stable grass-roots structure and improve the bearing capacity of the road. It can be used for laying the base and sub-base of highways and city roads.

Water conservancy project: The sand produced by VSI sand making machine can ensure the permeability and frost resistance of concrete. It is used in water conservancy projects, such as the concrete structure of dams and sluices.

Glass manufacturing industry: VSI sand making machine can produce quartz sand with high purity and suitable particle size, which can improve the transparency, strength and other properties of glass.

Environmental protection field: It can be used in the sulfur removal of thermal power and metallurgy industry, as well as the crushing of construction waste and other environmental protection projects.

What Should You Consider When Choosing VSI Impact Centrifugal Crusher?

If you are planning to buy a VSI Impact Centrifugal Crusher, then you need to consider many factors in advance, such as capacity, feed size, discharge aggregate size, application, price, service, return and so on. Here I have listed a few important parts for your reference:

Feeding size

The first thing you should consider is the feed size. Customers should probably know the size of the material aggregate before crushing. Because customized VSI Impact Centrifugal Crusher models are mainly divided according to the feed size.

Capacity

Capacity should also be one of the factors to consider. If you plan to crush a large amount of aggregate in a short period of time, it is better to choose a large capacity crusher. If there is enough time, a smaller size crusher may be more cost effective.

Price

VSI Impact Centrifugal Crusher cost is the most important aspect for customers to consider. It is very important for customers to choose a VSI Impact Centrifugal Crusher with the best price and within their budget. Chunlei offers different models of crushers with different prices. Please contact us and get the latest VSI Impact Centrifugal Crusher price.

Service

For mining machinery industry, choosing a reliable and serviceable VSI Impact Centrifugal Crusher manufacturer is very important for customers. Crushing production line is a complete set of solutions customized for customers. Therefore, it needs constant communication, follow-up and feedback. The best service can help customers save a lot of maintenance after-sales service costs.

For the mining industry, especially for large-scale mining machinery, it is especially important for customers to choose a reliable and well-served VSI Impact Centrifugal Crusher manufacturer. The crushing line is a complete solution customized for the customer. Therefore, both parties need constant communication, follow-up and feedback. Meticulous service can help customers save a lot of maintenance and after-sale costs.

What Can ChunLei Do for You About VSI Impact Centrifugal Crusher Service?

- Pre-sales service: 1.Assist customers to prepare the first construction plan; 2. Provide route guidance, reception at any time, and visit our factory at any time.

- On-sale service: 1. Provide example guidance at any time by phone or email; 2. Install, debug and inspect the equipment, and provide technical support through video.

- After-sales service: 1. Provide spare parts at the best price for a long time; 2. We provide 1 year warranty and technical support to ensure the smooth operation of the machine.

You may also want to know about ChunLei-FAQ

1. Are you a factory or a trading company?

We are factory, and in 2008 officially registered ChunLei Machinery.

2.How is the quality of your products?

Our products are manufactured strictly according to national and international standard, and we take a test on every equipment before delivery.

3.How about price?

We are factory and can give you lower price than the market, and we have a policy “In order to save time and absolutely honest business attitude, we provide the lowest possible quotation for any customer, and can give discounts as needed to the quantity” .

4. How long is the warranty?

Does your company supply the spare parts? One year. Spare parts for you at lowest cost.

5. How long is your delivery time?

7-10 days for the stock, 15-30 days for the mass production.

6. What is your payment method?

We usually accept T/T, L/C、Western Union payments;

7. If I need a complete mining rig, can you help us build it?

Yes, we can help you set up a complete production line and give you related professional advice. We had already build many mining projects in China & Overseas.

Customize Your crushing Solutions

Contact us now via email: info@miningmachinerys.com, or WhatsApp me, or fill in the form below.

1. Feeding Size.

2. What configuration do you need? (Crusher Type , VibratorScreening,Magnetic Separator, Sand Washing Machine, etc.)

3. ls there a Mining License?

4. Start time of project?

5. Other requirement.

Contact information: